PCB Surface Completion Arrangements Geniuses and Cons

PCB Surface completion structure the basic connection point between the board and the parts. Lately, their far reaching accessibility has overpowered a few electronic planners. This post desires to reveal a few insight into the upsides and downsides of the four most prevailing PCB surface completion arrangements available: Natural Solderability Additive (OSP), Electrolysis Nickel Drenching Gold (ENIG), Electroplated Nickel Gold and Inundation Tin or Silver. The accompanying post applies to Inflexible Printed Circuits Sheets (PCB) and Adaptable Printed Circuit (FPC).

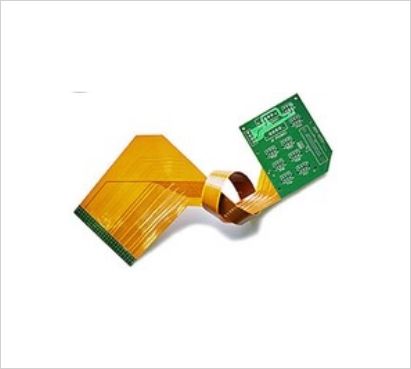

Note: PCBs are by and large made of inflexible materials and won’t twist during their application. FPCs are typically slender and made of materials equipped for twisting or potentially development during application. Handling and application necessities direct whether the PCB surface completion is electroplated, electrolysis, drenching or kept.

Conditions that impact PCB Surface Completion Determination:

Oxidation insurance of PCBs metal follows (typically copper).

Surface solderability for electrical and mechanical part connection.

Surface bondability for chip mounted parts utilizing gold and aluminum wire.

Any mixes of the abovementioned.

Mechanical applications (for example stress, strains and so on.).

Natural circumstances (for example temperature, relative stickiness and so forth.).

Mechanical contacts requiring scraped area opposition and oxidation security.

General Conversation of Accessible Surface completions

Natural Solderability Additive (OSP)

OSP has a restricted time span of usability. Its most continuous use is welding when the protectant is scattered during the interaction, consequently no extra expulsion processes are required.

Alert: when eliminated, the uncovered copper is presented and dependent upon oxidation. At the point when different completions are required on a similar PCB, OSP can be applied over different kinds of surface completion (for example wire holding and fastening, mechanical contact surfaces and welding, and so forth.).

Electrolysis Nickel Submersion Gold (ENIG)

ENIG is a generally involved surface completion for welding, aluminum wire wedge holding and mechanical contact focuses (connector cushions, test focuses, and so on.). The copper surface has an electrolysis nickel layer stored (150 miniature inches least) to seal the copper. A layer of gold is then saved to shield the nickel from oxidation and give a solderable surface to the nickel. The gold is assimilated and scattered into the weld. The gold is an inundation interaction and the thickness is self-restricting (2 to 3 miniature inches max).

The nickel layer is exceptionally weak and can’t be exposed to pressure or strains in the Z hub without breaking. Adaptable PCBs are particularly vulnerable to this with all areas subject to potential twisting upheld with rigidizing materials.

Alert: Inappropriately controlled ENIG handling can bring about powerless bind associations which may not be apparent and additionally bring about disappointment. A regular indication of disappointment is a level dark copper cushion after the joined part has been effectively gotten rid of.

Electroplated Nickel Gold

In the present complex circuits, this surface completion is exceptionally restricted in light of the fact that it expects that all surfaces to be plated must be electrically associated (for example an electrical charge should introduce for plate). These interconnections should then be broken to make the circuit practical. The plated nickel is entirely solderable and not expose to the solderability issues of ENIG. The plated gold has no restrictions on thickness and can uphold wire-holding processes like Thermo Pressure Holding (for example ball holding).

Alert: Thicker gold can bring about weld joints being too fragile while utilizing toxic fastens.

Inundation Tin and Drenching Silver

These cycles give solderable surfaces however will quite often have oxidation and stain gives that influence solderability. They are not generally utilized or accessible.

D

Ok

Yeah!

Mingalabar ❤

Appreciate.

Hello

This website is always successful.

ဟူးးးးးးးးးးးး💪

Clicked

Thanks a lot for clicked in it.

အသိပညာလည်းတိုးပွား ထောက်ပို့လည်းဖြစ်

That is a good tip particularly to those fresh to the blogosphere.Short but very accurate information? Many thanks for sharing this one.A must read article!My blog: low-carb diets popular

I do consider all of the concepts you haveintroduced for your post. They are very convincing and can definitely work.Still, the posts are too quick for beginners. May you please extend them a little from subsequent time?Thank you for the post.